The BVS accuracy throwing organization will serve sectors that desire the greatest quantities of top quality. The aerospace, car, healthcare, and energy businesses move to accuracy and precision casting because it is the most cost-effective way to generate a part with intricate geometries, for instance a individual metal aspect without welding. But the process is not the only permanent mold alloys benefit.

Along with offering a higher amount of dimensional accuracy for complicated components, the accuracy and precision casting process delivers layout mobility along with an outstanding work surface complete. It also will allow fabricators to use virtually any material to make a part, whether it is lightweight aluminum, metal, or nickel.

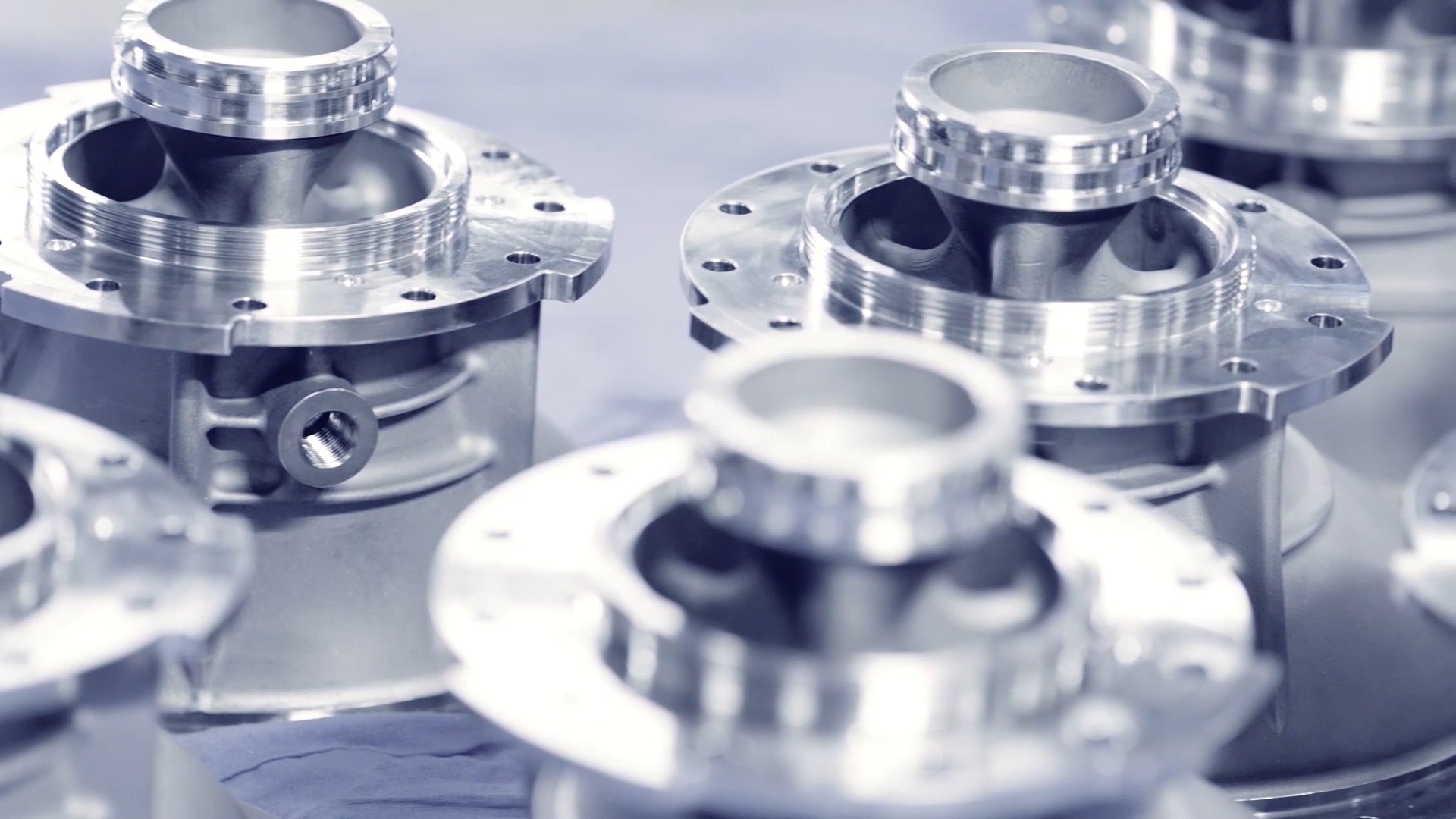

The different parts that benefit from the accuracy and precision throwing approach are aerospace rotor blades and tires and clutch parts and travel and pressure pulleys inside the vehicle business.

Rigid top quality regulates are area of the DNA in the BVS preciseness throwing organization. Final component reliability is determined by managing dimensional precision at each and every stage of manufacturing, from expert routine creation, via routine and mold growth, for all in-line specifications of the closing throwing.

To get a perfect complete

Additionally, Burnstein Von Seelen provides electroplating providers when organizations need that the items use a surface area complete that ensures durability and sweetness, nothing much better than having the electroplating professional services of the renowned organization.

They have substantial-technician devices that warranties a great complete, complying with all of overseas top quality requirements. Furthermore, Burnstein Von Seelen is ISO 9001 licensed, which guarantees that every its functions are fully handled to make items to specifications.

For greater aspect precision

Also, Burnstein Von Seelen has got the developing solutions of long term fungus alloys for firms that have to create huge pieces, ensuring that all the components has got the indicated specifications.

With metal molds or shells, far better way of measuring precision is obtained, even though the surface area excellence of the pieces obtained is enhanced. They can be mainly employed for the production of huge series of small or method-measured parts.